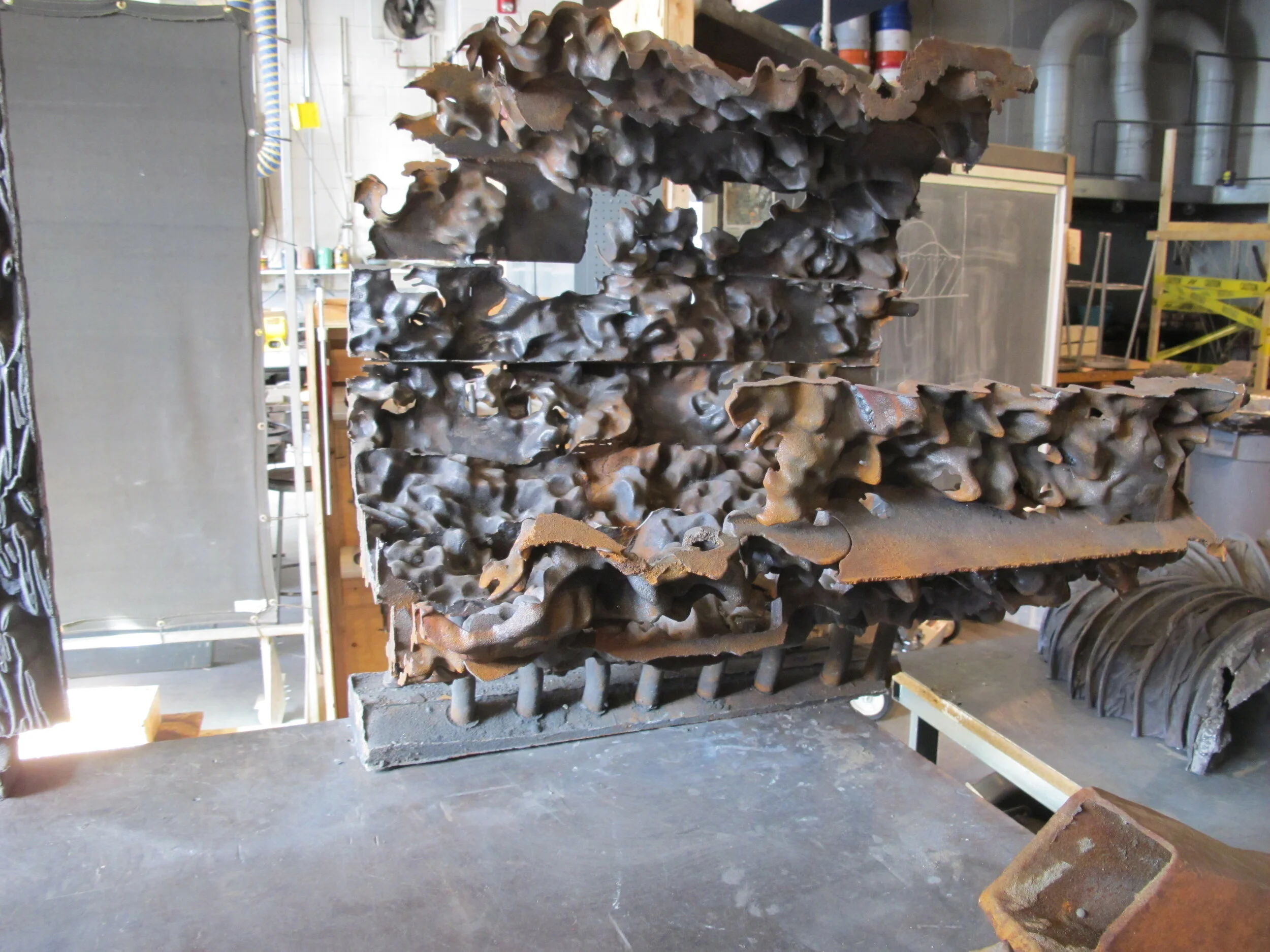

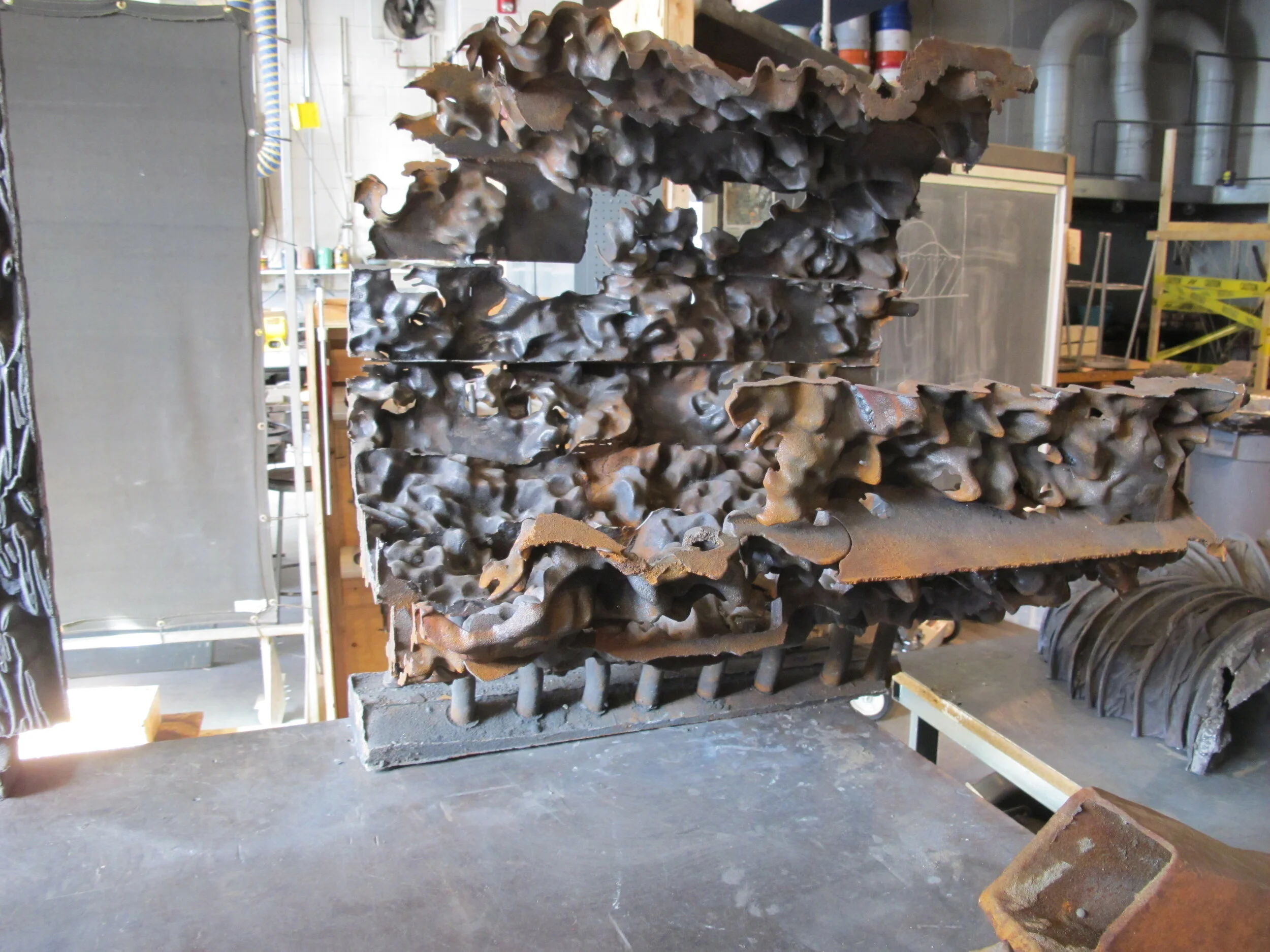

Hemoglobin cylinder was cast as a conference demonstration, “New Approaches to Draftable Pattern Making and CNC Technologies,” at the 8th International Conference on Contemporary Cast Iron Art at The Keystone Historic Furnace Site in Scranton, PA, in 2018. This project began with a computer model of a hemoglobin protein from an open source database for medical research. The model was sliced into horizontal layers and the surface textures were layered over a cylinder form using the modeling program Blender. The cylinder was then cut into 20 equal pieces and these models were then cut out of foam with a CNC router. The foam patterns were then molded in resin sand. I then took resin sand molds off of the existing sand mold pieces to create their exact opposite counterpart. The sand mold pieces were then assembled together leaving a space between them for the cast metal to flow into. An external gating system was created, also out of resin sand, and the entire assembly was cast as one mold. Scroll further to see images of the entire process.